CONNER TIERSCH - LSU PETROLEUM ENGINEERING

Project Summary

Sperm vitrification as an alternative approach to conventional cryopreservation (equilibrium freezing) allows quick and low-cost sample preservation and is suitable for small-bodied aquatic species with miniscule testis, fieldwork at remote locations, and small-scale freezing for research purposes. The goal of this present study was to develop operational prototypes of 3-dimensional (3-D) printed vitrification devices with innovative components that can accomplish comprehensive functionalities for practical repository development for aquatic species.

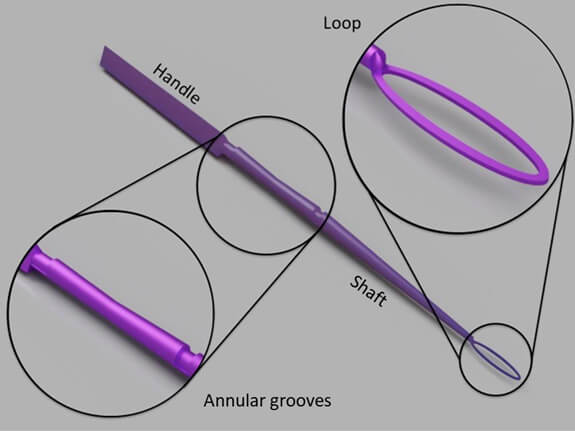

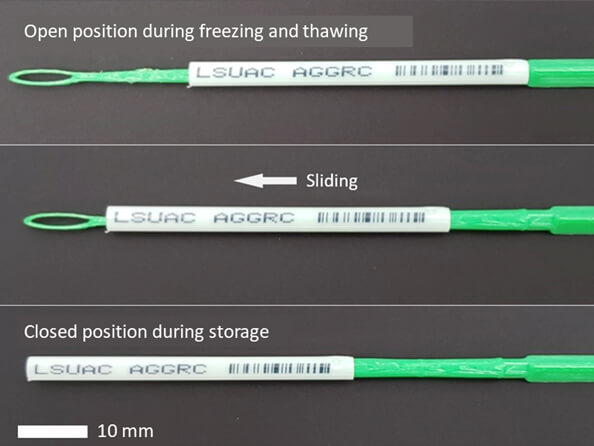

The design (Fig. 1) featured an elongated loop to suspend a thin film of sperm sample in cryoprotectant, a retractable sleeve to protect the vitrified samples and allow permanent labeling, a handle to facilitate processing and storage, and a shaft with annular grooves to guide positioning of the protective retractable sleeve (Fig. 2). To span a wide range of sample capacities and configurations, a total of 39 different configurations (3 loop lengths ×13 loop heights) were fabricated by 3-D printing with the thermoplastics polylactic acid (PLA) and acrylonitrile butadiene styrene (ABS).

A total of 86 devices were fabricated with ABS filament with a print failure rate of 9%, and 97 devices were fabricated with PLA filament with a failure rate of 20%. Major types of printing failures included disconnected loops, insufficient build surface adhesion, stringing, and inconsistent extrusion. The sample volume capacity ranged from 1-47 μL and had linear relationships to the loop lengths and layer numbers. Vitrified samples were observed in 10-mm and 15-mm loops fabricated with PLA and ABS but not in 20-mm loops. This study demonstrated the feasibility of development of standardized low-cost ($0.05 material cost) devices fabricated by 3-D printing with practical functions including vitrification, volume control, labeling, protection, and storage within conventional systems. These prototypes can be further developed, standardized, and used to assist development of germplasm repositories for aquatic species by user groups such as breeders, hatcheries, aquariums, researchers, and repository operators.